Medical device manufacturer Accuray partners with Alexandria Industries to save time, money and lives

For nearly 100 years radiation therapies have been on the front lines in the fight against diseases like lupus, epithelioma, and other forms of cancer. Because overexposure to radiation can cause long-term cell damage that could lead to the very thing—cancer—it tries to defeat, oncologists rely on sophisticated radiotherapy medical equipment that precisely delivers the radiation to cancerous cells, while preserving the surrounding healthy cells.

One of the leading radiation oncology companies that is helping patients live longer, better lives is Sunnyvale, Calif.-based Accuray. Like many medical equipment manufacturers, Accuray relies on tightly orchestrated relationships with its component suppliers to help design, develop, and integrate components to bring to market leading equipment, such as its TomoTherapy® System, which is manufactured at its Madison, Wis., facility.

The TomoTherapy System is the only radiation system specifically designed for integrated, 3D image-guided, intensity modulated and 3D radiation therapies.

The TomoTherapy System involves complex computing and hundreds of mechanical parts. It is the only radiation system specifically designed for integrated, 3D image-guided, intensity modulated radiation therapy (IMRT) and 3D conformal radiation therapy. Based on a computed tomography (CT) scanner platform, the TomoTherapy System enables helical dose delivery through continuous 360-degree gantry rotations for specified beam angles. These unique features, combined with daily 3D image guidance, allow oncologists to precisely apply an individualized dose to any target volume, during each treatment fraction.

Challenge

Each component contributes to overall equipment accuracy and uptime performance. The TomoTherapy System boasts one of the most reliable uptime rates in the industry at approximately 99 percent, but when shortcomings with a supplier’s couplings for the system’s electro/pneumatic/mechanical assembly threatened its accuracy and uptime, Accuray sought an immediate solution.

Coupled to a pneumatic actuator, the system’s 64 mechanical leaves shutter open and close to deliver the prescribed modulated dosage of radiation to the diseased cells. Instances of the couplings used to connect the leaves with the actuator breaking would prompt a system error, causing the machine to safely shut down.

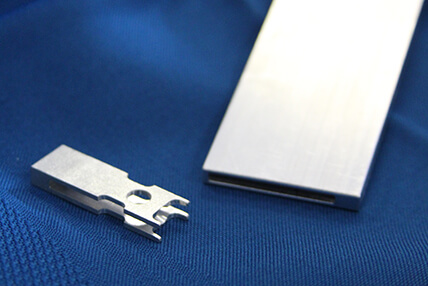

The couplings were machined from stock steel using electrical discharge machining (EDM)—a complicated machining process that requires several manufacturing steps—and come with a relatively high part price when included with other processes for this part.

When Bradley Brunker, a senior sustaining engineer from Accuray’s Madison campus examined solutions for the failing couplings, his criteria were both technical and economical. Industry-leading performance was mandatory and he also wanted to be able to reduce the full assembly part count, part cost, and, ultimately, the labor cost to assemble it. And he needed to do it fast.

Solution

When thinking about how he should change the coupling to enhance its mechanical properties, Brunker determined the component should be extruded from aluminum instead of machined from steel. His previous experience with extruded aluminum products proved to him that the metal alloy’s properties combined with hard-coat anodizing would give him the reliability he needed in addition to the lower cost per part he was seeking.

Brunker turned to Minnesota-headquartered Alexandria Industries to help design, engineer, and manufacture a component that all treatment facility sites—and their patients—could rely on.

Design engineers with medical market expertise from Alexandria Industries worked closely with Brunker to create the part’s die and ensure the extruded pieces were made to exact specifications using Finite Element Analysis (FEA) studies to prove part measurement.

They identified slight design variations from the original design that would improve the part’s overall strength and durability and assure repeatability from the tooling.

According to Rob Zahn, vice president of manufacturing at Accuray, “The Alexandria Industries engineering team assigned to Bradley’s project worked closely with him to tweak the design. Their experience, industry knowledge on finishing techniques, and ability to communicate clearly and efficiently saved a significant amount of design time.”

The aluminum extruded component is machined and anodized the surfaces to the exact specified hard-coat thickness tolerance to increase wear resistance and simplify mating assembly for its intended snap-fit design.

After extruding the components, Alexandria Industries technicians machined and anodized the surfaces to the exact specified hard-coat thickness tolerance to increase wear resistance and simplify mating assembly for its intended snap-fit design.

As a final manufacturing step, an identification tag was laser etched on each component. This tag is recorded so Accuray and Alexandria Industries can track and monitor each component for quality assurance purposes.

“From the first design to final production and delivery, Alexandria Industries kept Bradley informed every step of the way,” Zahn said. “He didn’t have to babysit at all, which was probably the most refreshing part for us.”

Results

There were some premature wear issues with the previously EDM-produced couplings – Accuray wanted to extend the life of the couplings to at least 10 years. Accuray performed four months of mechanical testing on multiple prototype assemblies, running numerous sets of the coupling components from Alexandria Industries through 10 million cycles. The result: zero failures.

Another goal for this project was to lower the total part count and assembly labor cost. Because the coupling was extruded, the design could be shaped in such a way that it could snap-fit to its mating components. The leaf, coupling and another redesigned component easily snapped together and cut the assembly labor by 30 to 60 minutes for each completed assembly.

Using an aluminum-extruded part also cut component manufacturing costs by nearly 90 percent and took only a quarter of the time to produce. And because of the couplings’ snap-fit geometry, Accuray also was able to eliminate a tool previously used for assembly.

The quality assurance senior auditor for the project was so impressed with the product and Alexandria Industries’ performance that it has since been added to Accuray’s list of approved vendors. In fact, it is the only aluminum extrusion company on the list.

Accuray began putting the updated sub-assemblies in field in mid-2012 and has installed approximately 10,000 new coupling components to date.

“Part of the high cost to develop new medical device products can be attributed to outsourcing component manufacturing from various suppliers,” Zahn said. “Managing these relationships takes a heavy financial and logistical toll, slowing the time to market and driving up the cost. By working with Alexandria Industries, we were able to streamline the process, which saved the company something much more important than money. It saved us time and helped ensure our TomoTherapy equipment stays up and running for the people who need it most – those with cancer.”

*As appeared on Medical Design Technology website (August 2013)