More than one aluminum alloy could be suitable for your product component needs, which is why you should not set your mind on a certain alloy. At least without understanding the value different alloys can bring to your extrusion profile.

At Alexandria Industries, we understand the different alloy elements and their characteristics. We understand details, such as which aluminum alloys tend to be harder or softer, which have higher mechanical strength or are best when machining or welding.

To determine the best alloy for your aluminum extrusion needs, it is helpful to have a basic understanding the seven alloy series – and their elements. When adding aluminum with certain elements, such as magnesium and silicon, the aluminum can be stronger, lightweight or corrosion resistant. By learning the different series of alloys and their general applications, you can narrow down your options significantly.

Major Alloying Elements

| Wrought Alloy Designation | Major Alloying Elements and Typical Alloy Characteristics |

| 1xxxx Series | Minimum 99% aluminum High corrosion resistance. Excellent finishability. Easily joined by all methods. Low strength. Poor machinability. Excellent workability. High electrical and thermal conductivity. |

| 2xxx Series | Copper High strength. Relatively low corrosion resistance. Excellent machinability. Heat treatable. |

| 3xxx Series | Manganese Low to medium strength. Good corrosion resistance. Poor machinability. Good workability. |

| 4xxx Series | Silicon Not available as extruded products. |

| 5xxx Series | Magnesium Low to moderate strength. Excellent marine corrosion resistance. Very good weldability. |

| 6xxx Series | Magnesium & Silicon Most popular extrusion alloy class. Good strength. Good extrudability. Good corrosion resistance. Good machinability. Good weldability. Good formability. Heat treatable. |

| 7xxx Series | Zinc Very high strength. Poor corrosion resistance. Good machinability. Heat treatable. |

Industry continues to develop new alloys to meet the needs of today’s changing and varied marketplaces. As of June 2018, there are more than 640 alloys registered with the Aluminum Association―not including proprietary alloy variants.

The 6000-Series Alloys

The 6xxx series of alloys is the favored choice among many industrial designers, due to the large number of application uses. The alloy is easier to extrude, form and machine. The easier an alloy is to extrude (push through the press) the more options you have in terms of shapes, including hollow shapes. Extruding the 6xxx series alloys, puts less stress on die tools and decreases wear.

This alloy series also is heat-treatable for increased strength, and corrosion resistant for harsh environments. It also allows for both chemical and mechanical finishing for enhanced product aesthetics. See the Aluminum Extruders Council Aluminum Manual, to learn more about the different alloys and their characteristics.

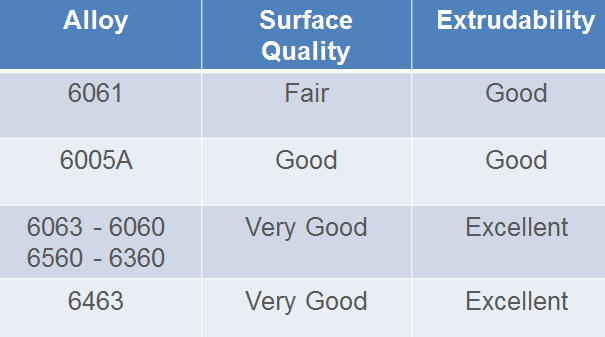

Extruders commonly use the 6000-series of alloys to make their customers’ components. The alloys within the series naturally share similarities, but there are also slight differences between them. For instance, when looking at the 6063 and 6061 alloys, the 6063 alloy will provide a better surface finish due to its lower amounts of silicon and magnesium. The 6061 alloy has slightly stronger mechanical properties due to its higher amounts of silicon and magnesium. Both alloys are machinable. See this table of common aluminum alloys and their ease of extrudability.

Educate yourself on the different alloys to understand which ones have the physical properties and characteristics you need. Stay open regarding alloy choice. There may be one or more alloys to use for your part.

Choose an Alloy Based on Product Needs

So what alloy should you choose? When looking at your component’s design, consider the following end-use applications:

- Functional needs – What will your component need to do? Do you need thin walls or an internal web for greater strength? Does your part have fins to cool the air in an electronic application? Will it need to absorb the impact in a vehicle crash?

- Aesthetic needs – What is the cosmetic requirement of your component? Does it need a shiny finish or a matte finish? Does it need color?

- Surface finish needs – Does your component need anodizing to protect it from harsh environments.

- End-use applications – What are the strength and weight requirements for your component? Will it need to be strong to serve as a hinge in an industrial housing application?

- Downstream manufacturing – Will you need follow-on machining, welding or assembly?

When selecting your alloy, it is also important to consider any possible mating components or sub-assembly needs your part may have.

Always discuss alloy options with your extruder to determine the alloy that is right for your product needs. At Alexandria Industries, our goal is to understand your component’s features and physical characteristics, so we can help you choose the best alloy to meet your needs.

[i]Aluminum Extrusion Manual, Aluminum Extruders Council, www.aec.org