Among the finishing options available, mechanical finishing imparts a surface texture to enhance your part’s look and feel.

Our mechanical finishing services include buffing, brushing, bead blasting and tumbling. Each technique generates different types of surface textures – from rough or patterned to a mirror finish.

If your product design requires a particular surface finish, improved surface quality, or to prepare for various final cosmetic finishes, consider the following types of mechanical finishes to enhance your products look and feel.

After extruding your components, we can create this attractive cosmetic surface finish that replicates polished chrome.

Bead blasting produces a unique granular appearance and comes in a range of textures. We work closely with a partner supplier to perform this operation for you, further simplifying supply chain management.

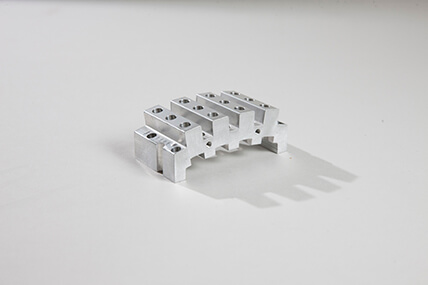

A tumbled finish on your components shows a galvanized appearance. The degree of shine, spangled, or matte grey appearance, depends on the type of media (abrasive material) and the amount of tumbling time.

There are a variety of tumbling media available, including ceramic, plastic, or synthetic media. Different media will have a different effect on the finished look and feel of your components.

We can tumble your entire part to eliminate swirl marks that occur from normal end-brush deburring machines. Tumbling also eliminates flow lines from the extrusion process. This type of mechanical finishing can serve multiple purposes such as deburring, washing, and polishing.